Traceability – All material is fully heat and lot traceable, allowing us to track products from raw material to finished goods.ġ00% testing for reliability and safer installation - Every foot of CNG Plus Tubing undergoes 100% hydrostatic testing and positive material identification.Ġ.500 in. CNG Plus tubing has superior corrosion resistance over standard stainless steel tubing. This allows installers to identify the correct tubing used in their application.īetter Corrosion resistance - With a 2.5% min. Product Identification - Wall thickness, maximum allowable pressure, tubing size and thickness are clearly printed on the layline of the tube. Increased installer and operator confidence – The entire length of CNG Tubing is 100% pressure tested and passes Positive Material

Improved system safety and reliability - Using one continuous run of tubing eliminates potential leak points.

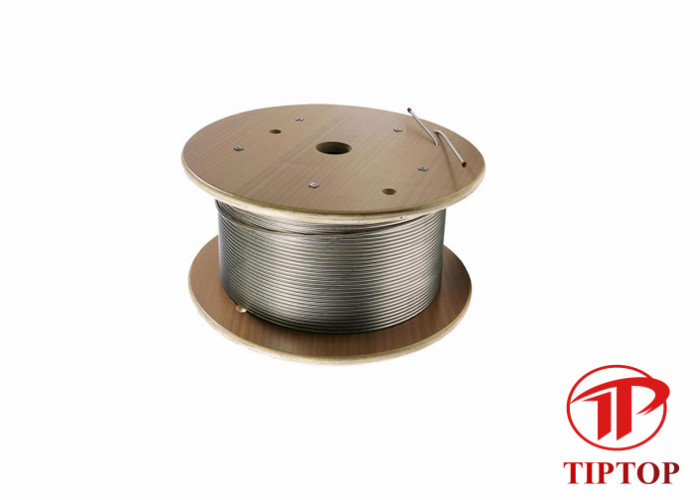

Significantly reduced installation costs – Installing continuous-length,seamless CNG Tubing takes much less time and effort than welding lengths of stick tubing. Higher flow - Larger ID than standard wall thickness means greater flow. The right fit - Specific wall thickness targeted at CNG applications to achieve 5500 psig pressure ratings. This eliminates welding labor and other costs associated with using stick tubing and pipe for underground and above ground lines. Coiled tubing is provided continuous lengths up to 672 ft in 1/2 in and 300 ft in 3/4 tubing. This tubing has optimized wall thicknesses designed the higher pressures associated with transporting compressed gas while maintaining the convenience of coiled tubing. SSP CNG Plus 5500 PSIG stainless steel coiled tubing is specially engineered for CNG stations applications.

0 kommentar(er)

0 kommentar(er)